Artworks in ancient times are fascinating, especially sculptures. Considering the state of technology in 1501-1504, great artists like Michelangelo di Lodovico Buonarroti Simoni had a lot on their plates. The sculptors, in ancient times, made sculptures with perfect finishes with simple tools. Imagine what these great artists would have done with 5-axis CNC milling. One thing for sure, we would have a lot of sculptures to look back too.

When you hear of 5-Axis machining, your thoughts run wild from expensive, complex machinery and high tech tooling. 5-Axis machining is not that complicated. To understand 5-Axis machining, think of a tool that can simultaneously work on different parts of a metal block to produce a part or prototype. Sounds convenient, right? Now, let us get back to the real world.

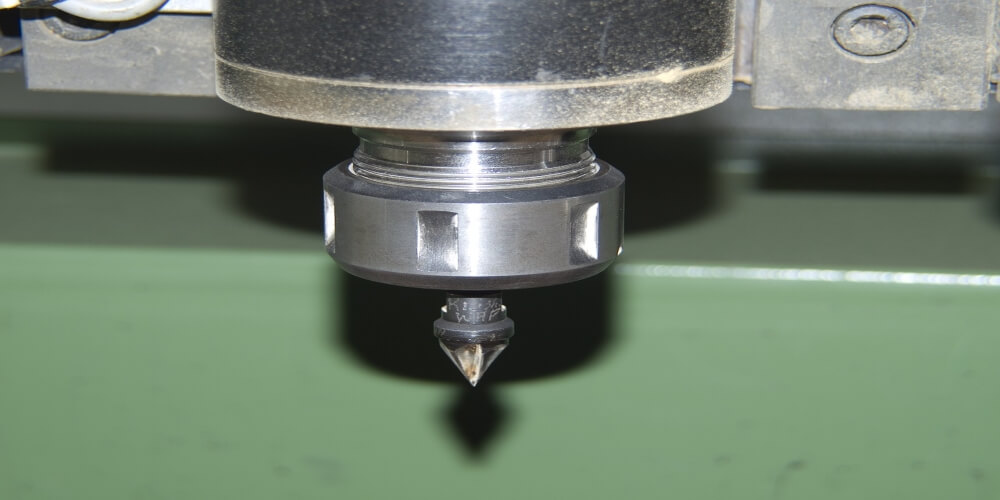

5-Axis machining involves using a machining center where the cutting tool moves (revolves) along the X, Y, and Z axes and rotates around the A, B (or C) axes. It may sound technical, but one thing about CNC machining is run by a computer using computer-aided designs. With 5-Axis, you have the advantage of a multidirectional approach to the materials used in part and prototype making.

Benefits of using 5-Axis machining

Industries that have integrated 5-Axis machining in their production process are enjoying numerous benefits. The most evident is increased production due to the reduced time required for machining.

Minimal setup

5-Axis machining allows you to minimize the number of setups required when tooling. The cutting tool has a multidirectional approach to the part being machined. 5-Axis machining can work on one part along multiple axes, simultaneously removing the need for multiple set ups. Your CNC shop will have more space; you could even get yourself a 3D printer to ramp-up production even higher.

Complex designs

The cutting tool in a 5-Axis machine can move on multiple axes allowing it to work with tight geometries to make complex designs. Sectors like the automotive industry can benefit from 5-Axis machining. Car parts like the engine and hypoid gears require complex geometries when milling, which 5-Axis machines provide easily.

Rotational Accuracy

Some parts require different positioning when machining, and when moving them, rotational accuracy becomes a problem. When moved, it may be hard to retain the original position to ensure that the cutting tool moves along the same trajectory. With a 5-Axis machine, there are minimal or no changes. This means that rotational accuracy is not tampered with.

Fast production

5-Axis CNC machining makes the production of parts and prototypes due to faster material removal. You can produce parts within a short time and replicate the same. It is ideal for mass production of the same type of part. Industries like the aerospace and automotive can hire custom 5-Axis machining services for part and prototype production. Since prototyping is a race against time, 5-Axis machining is an indispensable tool for rapid prototyping.

5-Axis machining allows for fast production and higher precision parts. Since it allows you to produce complex, it is an excellent option for the aerospace and automotive industry.